Oily Stone Processing Plant Getting Oil

1. Plant Features: 1) widely usage Can be used for tyre 5-10cm,plastic,rubber ,oil sludge, cooking waste ,live waste, oi;

Basic Info.

| Model NO. | xhlx-40-60 |

| Working Area | 300 Square-Meters |

| Heating Fuel | Gas/Oil |

| Type | Environmental Friendly |

| Input | Tyre Scrap |

| Power | 23kw |

| 24hour Process Capacity | 40ton |

| Plant Name | Oily Stone Processing Plant Getting Oil From Sto |

| Transport Package | Sea Worthy Packing |

| Specification | XHLX-40-60 |

| Trademark | XHZT |

| Origin | China |

| HS Code | 84198990 |

| Production Capacity | 25sets/Month |

Product Description

1. Plant Features:

1) widely usage

Can be used for tyre 5-10cm,plastic,rubber ,oil sludge, cooking waste ,live waste, oil sand ,oily soild

2) static pyrolysis ,getting higher quality oil, less dust in oil

3) large capacity

24hours produce 20-30 Ton material

4) continuous pyrolysis, no need cooling reactor, saving fuel, saving working time

5) The plant can working 25dyas*24hours without stop, fully continuous

6) Continuous feeding without stop

7) Continuous slag out without stop

8) Non-liquid gas can be reused to support heating for heating reactor , saving fuel energy

9) good pressure tightness, safe

2. Technical parameter

Reactor size | (L*W*H)6*2*2.5M |

volumn | 30/60M3 |

material | Q345R/Stainless steel |

Work pressure | Normal pressure/slightly negative pressure |

Process capacity /24hours | 30/60 Ton tyre |

20 /40 Ton plastic | |

Oil sludge 20-25/40-60Ton | |

Oil sand 20-30/40-60 | |

output | Base oil |

Working principle | Oxygen free pyrolysis |

workers | 1 |

power | 20/40kw |

voltage | 220v/380v |

Power consumption/24hours | 230 kw |

Water consumption | 2-3/4-6Ton |

Feeding time | Continuous feeding |

Carbon discharge time | Continuous slage out |

working life time | 4-5yeat |

Slag temperature | 150ºC |

Fuel | Gas, oil |

Pyrolysis way | Static pyrolysis, non-rotate |

Slag way | Continuous slag out |

Dust smoke temperature | 350ºC |

Pyrolysis temperature | 280-350ºC |

Max-temperature | 600ºC |

oil come temperature | 350ºC |

Raw material delivery speed | 0.4-2m/min |

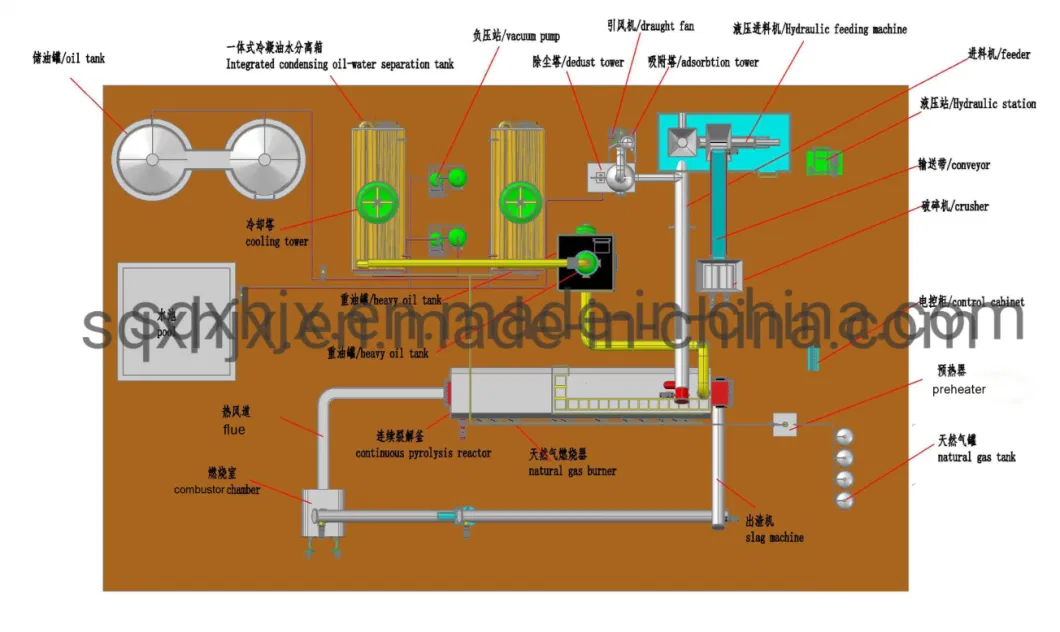

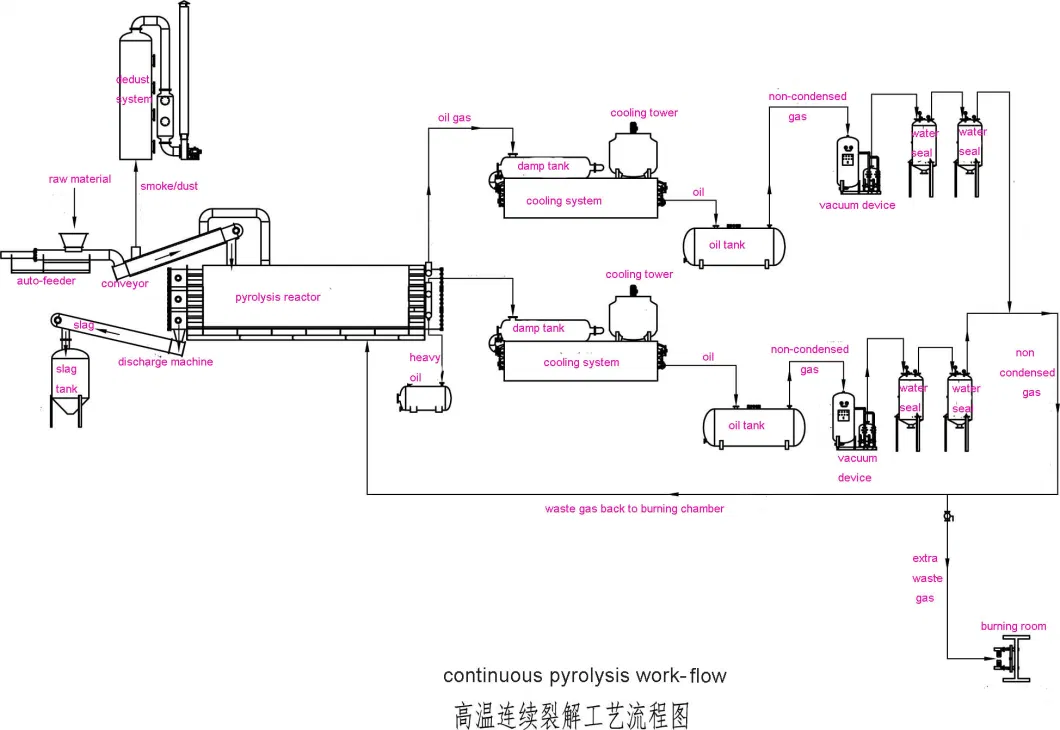

3.Work-flow

4. The difference bettween batch pyrolysis ,semi-continuous pyrolysis and fully continuous pyrolysis plant

Type | Feeding way | Heating way | Heating fuel | Reactor type | Pyrolsysis way | environmental effect | Featurs |

Batch | By human | Direct /indirect heating | Coal, wood, oil, gas | Round type/cylinder | Rotation pyrolsysis | environmental | After one batch need to cool down |

Semi-continuous | Auto-feeder | Direct /indirect heating | Coal, wood, oil, gas | Round type/cylinder | Rotation pyrolsyis | environmental | Need to cool down to slag |

Fully continuous | Auto-feeder | Indirect | Oil,gas | Cuboid/rectangular | Static pyrolsysis output oil with less dust, oil with better quality | Less dust, more environmental | No need to cool Saving fuel and working time |

Working details:

batch type:

one day one batch, day time heating pyrolysis, night time cooling .

semi-continuous type:

First time feeding 10Ton and heating, after 8 or 6 hours feeding second time 6 Ton and heating and pyrolsyis for another 6 hours

then feeding third time 4 Ton . And continue heating, after 5hours, this 5 Ton raw material complete pyrolsyised ,then cooling down reactor , and slag out. Semi-continuous pyrolysis means feeding 3 times (intermittent) and slag one time.

Compare to batch type, this semi-continuous plant just add auto feeder. this is not real meaning continuous.

fully continuous pyrolsysis,

continuous feeding without stop and the plant running 24hours*26dayst untill plant overhual.

continuous feeding , and continuous slag out.

You may also like

Send inquiry

Send now